MENU

Category

- AUTOMATION

- MACHINE DEVICE

- CONSTRUCT DEVICE

- FACTORY DEVICE

- TESTING DEVICE

- TENSION MEASUREMENT

- TRACTION MEASUREMENT

- TORQUE MEASUREMENT

- RPM MEASUREMENT

- THICKNESS MEASUREMENT

- STIFFNESS MEASUREMENT

- DISTANCE MEASUREMENT

- VISCOSITY MEASUREMENT

- FLOW/LEVEL MEASUREMENT

- DEPTH MEASUREMENT

- DIAL INDICATOR

- MICROMETER

- CALIPER

- MEASUREMENT ACCESSORIES

- MICROSCOPE

- MAGNIFIER

- TENSION TESTOR

- LINEAR SCALE

- TEMPERATURE MEASUREMENT

- WIND MEASUREMENT

- SOUND MEASUREMENT

- SPEED MEASUREMENT

- DENSITY MEASUREMENT

- CURRENT MEASUREMENT

- WEIGHT MEASUREMENT

- CALIPERS

- ENVICONMENT DEVICE

- SOLAR PRODUCTS

-

AUTOMATION

AUTOMATION

-

MACHINE DEVICE

MACHINE DEVICE

-

CONSTRUCT DEVICE

CONSTRUCT DEVICE

-

FACTORY DEVICE

FACTORY DEVICE

-

TESTING DEVICE

Category

TESTING DEVICE

Category- TENSION MEASUREMENT

- TRACTION MEASUREMENT

- TORQUE MEASUREMENT

- RPM MEASUREMENT

- THICKNESS MEASUREMENT

- STIFFNESS MEASUREMENT

- DISTANCE MEASUREMENT

- VISCOSITY MEASUREMENT

- FLOW/LEVEL MEASUREMENT

- DEPTH MEASUREMENT

- DIAL INDICATOR

- MICROMETER

- CALIPER

- MEASUREMENT ACCESSORIES

- MICROSCOPE

- MAGNIFIER

- LINEAR SCALE

- TEMPERATURE MEASUREMENT

- WIND MEASUREMENT

- SOUND MEASUREMENT

- SPEED MEASUREMENT

- DENSITY MEASUREMENT

- CURRENT MEASUREMENT

- WEIGHT MEASUREMENT

-

ENVICONMENT DEVICE

ENVICONMENT DEVICE

- Home Page

- Product

- AUTOMATION

- RELAY

- Thermal overload relay J7TC OMRON

Thermal overload relay J7TC OMRON

Price :

Contact

Quantity :

Status :

In Stock

-

Product No4103

-

Brand

-

OriginJAPAN

-

Guarantee12 MONTHS

Mô tả ngắn:

Motor Protection from Overload and Phase -loss by Combination with J7KC for up to 2.2 kW (240 VAC) *, 5.5 kW (440 VAC) * Based on JIS C 8201-4-1

DO YOU NEED SUPPORT ?

Product Description

Thermal overload relay J7TC OMRON

Ngan Anh Phat Co., Ltd specializes in providing genuine products Thermal overload relay J7TC OMRON from the manufacturer Omron, originating from Japan, to the Vietnamese market.

Outstanding features of the Thermal overload relay J7TC OMRON

- motor protection: detects and trips in case of overload or phase loss, ensuring safety and preventing damage to the motor.

- combination with j7kc contactor: forms a comprehensive motor protection system, supporting power ratings up to 2.2 kw (240 vac) and 5.5 kw (440 vac).

- push-in plus connection technology: enables quick and easy wiring, saving time and improving maintenance efficiency.

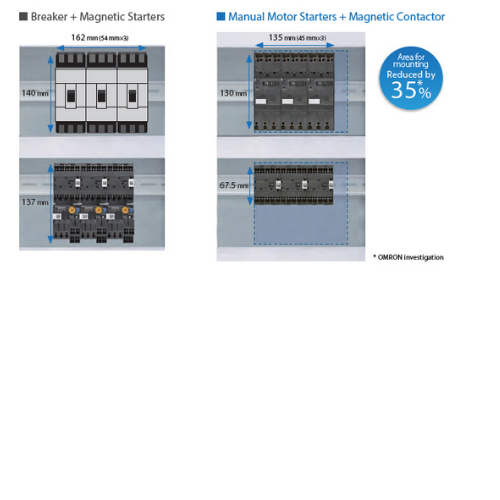

- compact design: with a width of only 45 mm, it fits easily into control panels, saving space.

Specifications

Specifications

Ratings/Specifications

| Main circuit rating |

Trip class | 10 A | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 3-pole load operation (At 20°C ambient temperature) IEC 60947-4-1/ JIS C 8201-4-1 |

Limit operation |

No operation (cold start) | 105% (less than 2 hours) *1 | |||||||

| Operation (hot start) | 120% (less than 2 hours) *1 | |||||||||

| Operation when overload occurs (hot start) |

150% (less than 2 minutes) *1 | |||||||||

| Operation when locking occurs (cold start) |

720% (over 2 s up to 10 s) *1 | |||||||||

| 2-pole load operation (At 20°C ambient temperature) IEC 60947-4-1/ JIS C 8201-4-1 |

Phase less protection device | With phase failure protection device | ||||||||

| No operation (cold start) | 2 poles 100%/1 pole 90% *1 | |||||||||

| Operation (hot start) | 2 poles 115%/1 pole 0% (less than 2 hours) *1 | |||||||||

| Ambient temperature compensation performance |

Ambient temperature 40°C |

No operation (cold start) | 100% (less than 2 hours) *1 | |||||||

| Operation (hot start) | 120% (less than 2 hours) *1 | |||||||||

| Ambient temperature -5°C |

No operation (cold start) | 105% (less than 2 hours) *1 | ||||||||

| Operation (hot start) | 130% (less than 2 hours) *1 | |||||||||

| Auxiliary circuit rating |

Ratings based on IEC 60947-5-1 |

Rated voltage range (V) | 24 | 100-120 | 200-240 | 380-440 | 500-600 | |||

| Rated operational current (A) |

AC-15 (Coil load) |

NC contact | 3.0 (0.5) *2 | 2.5 (0.5) *2 | 2.0 (0.5) *2 | 1.0 (0.5) *2 | 0.6 (0.5) *2 | |||

| NO contact | 3.0 (0.5) *2 | 2.5 (0.5) *2 | 1.5 (0.5) *2 | 0.75 (0.5) *2 | 0.6 (0.5) *2 | |||||

| DC-13 (Coil load) |

NC contact | 1.1 (0.3) *2 | 0.28 | 0.14 | --- | --- | ||||

| NO contact | 1.1 (0.3) *2 | 0.28 | 0.14 | --- | --- | |||||

| Conventional free air thermal current (Rated carry current) |

5 A | |||||||||

| Ratings based on UL 508 |

Rated carry current (A) | 5 | 1 | |||||||

| Rated voltage (V) | 120 AC | 240 AC | 480 AC | 600 AC | 125 DC | 250 DC | ||||

| Contact closed current (A) | 30 | 15 | 7.5 | 6 | 0.22 | 0.11 | ||||

| Breaking current (A) | 3 | 1.5 | 0.75 | 0.6 | 0.22 | 0.11 | ||||

| Rating code | B600 | Q300 | ||||||||

| Minimum operate voltage/current (reference value) | 5 VDC, 3 mA | |||||||||

| Contact resistance (reference value) | 50 mΩ max. (6 VDC, 1 A, voltage drop method) | |||||||||

| Contact structure | Single-break | |||||||||

| Contact material | Ag alloy | |||||||||

| Rated insulation voltage | 690VAC | |||||||||

| Rated impulse dielectric strength | 6 kV | |||||||||

| Rated frequency | 50/60 Hz | |||||||||

| Vibration resistance | Vibration: 10 to 55 Hz, acceleration: 15m/s2 | |||||||||

| Shock resistance | Shock value 50 m/s2 | |||||||||

| Degree of protection | IP20 (IEC60529) | |||||||||

| Operating temperature | -10 to +55°C (however, daily average shall not exceed 35°C) | |||||||||

| Ambient storage temperature | -40 to +65°C (no condensation or icing) | |||||||||

| Relative humidity | 45% to 85% RH (no condensation or icing) | |||||||||

| Altitude | 2000 m max. | |||||||||

| Weight | 110 g | |||||||||

| Applicable standards | Safety standard | EN 60947-4-1 (IEC 60947-4-1), UL 60947-4-1, CSA 22.2 No.60947-4-1, CCC GB/T 14048.4, UKCA |

||||||||

*1. Ratio to dial settling current

*2. () indicates the contact rating when set to auto release

Product Reviews

ABOUT NGAN ANH PHAT

CUSTOMER SUPPORT

CUSTOMER SERVICES

like facebook

NGAN ANH PHAT CO.,LTD

- D3, Dong Khoi, Group 23, Quarter 35, Tam Hiep Ward, Dong Nai Province, Vietnam

- (+84) 2513 857 563

- info@ngananhphat.com, sales@ngananhphat.com

- www.ngananhphat.com

Copyright © CÔNG TY TNHH NGÂN ANH PHÁT